Various household appliances and gadgets are gradually turning life from a routine into a pleasant pastime. We are used to the fact that a robot vacuum cleaner cleans the apartment, a dishwasher washes dishes, and multifunctional washing and drying machines are responsible for the cleanliness of things. However, all of the above devices can sometimes fail, thereby bringing great inconvenience. Today we will talk about the breakdown of the dryer. Specifically, we will analyze why the Whirlpool dryer stops heating.

There is a list of the most common reasons that lead to such a breakdown. At the same time, there are nuances that determine the procedure for repairing electric and gas dryers.

Most often, Whirlpool electric and gas dryers stop heating due to the fact that the heating element built into them has burned out. Also, a breakdown can be caused by a failure of the gas valve solenoid, a faulty fuse, a thermal switch and a thermostat. The list of reasons for the absence of the heating process also includes a breakdown of the igniter and the flame sensor.

We will analyze in more detail each cause and give ways to eliminate the identified malfunctions.

Whirlpool electric type dryer does not heat up

Burnt out heater

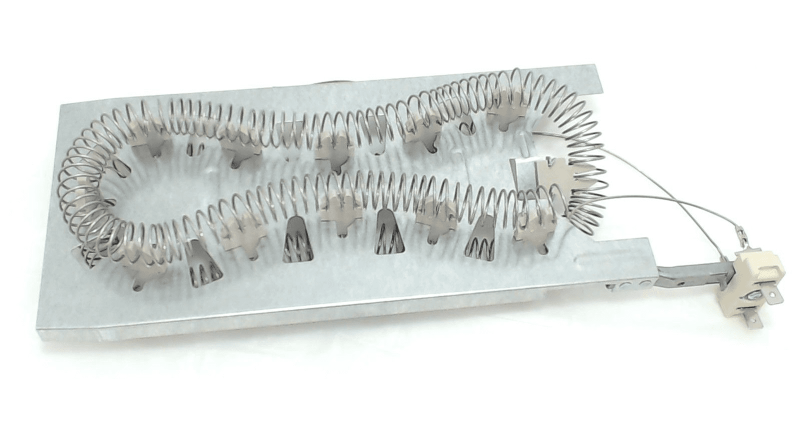

The electric dryer will only work correctly if the heating element is in perfect order. It is thanks to this element that the air in the drum is heated to the optimum temperature.

The location of this part depends on the modification of the washing machine. In some models, it is located inside the case, in others it is located directly behind the drum.

With active use, the heating element can wear out and fail over time. In this case, the Whirlpool dryer simply stops heating. If you assume that the problem lies precisely in this element, then you will have to find it and check for operability.

The first step is to check the integrity of the wires that come from the heater. After all, the matter may be that just some postings have departed. In the event of a fault in the wiring or a lack of continuity in the element, you will have to replace it with a new one.

The fuse has blown

Tumble dryers manufactured since the 1980s are equipped with fuses. This addition is necessary in order to prevent possible overheating of the dryer. The element provides adequate safety and minimizes the risk of fire.

The thermal fuse works in conjunction with the heating element. When it burns out, the dryer stops heating. If you find that the dryer turns things over, but there is no hot air, then you need to check the fuse and replace it.

Dealing with this is quite easy:

- The first step is to de-energize the dryer by unplugging it from the mains.

- Next, you need to remove the vent.

- After that, rearrange the machine so that free access to the rear panel opens. It needs to be removed.

- After that, find the fuse, it is located on the fan housing.

- Remove the element by removing the terminals and screw and replace it with a new one.

- Secure the new part with clamps and screw. Replace all wires.

In addition, it is necessary to identify the root cause that led to the blown fuse. After all, it is likely that a new part will also quickly fail.

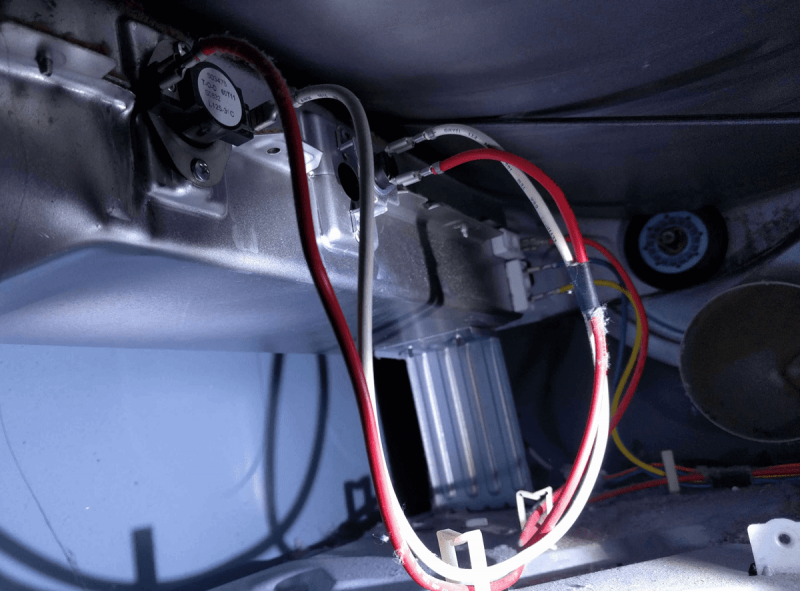

Cyclic thermostat broken

The cyclic thermostat provides temperature control inside the fan casing. It is necessary to activate and deactivate the heating element.

Failure of this mechanism can lead to serious consequences. Without his participation, the heating element may be active for too long, thereby creating too high a temperature inside the drum.

Checking the continuity of this element is quite problematic. Closed contacts inside the part do not open until the temperature rises. We will tell you a few life hacks that will allow you to conduct the desired test.

- Repair work should only be started after the dryer has been disconnected from the power supply.

- Locate the cyclic thermostat (the part is usually located on the thermostat housing) and carefully dismantle it.

- Take your multimeter and set it to Rx1, then place the pins on the terminals located on the thermostat.

- The device should show 0 or infinity. Other indicators indicate a malfunction of the part.

An element that no longer works will have to be replaced.

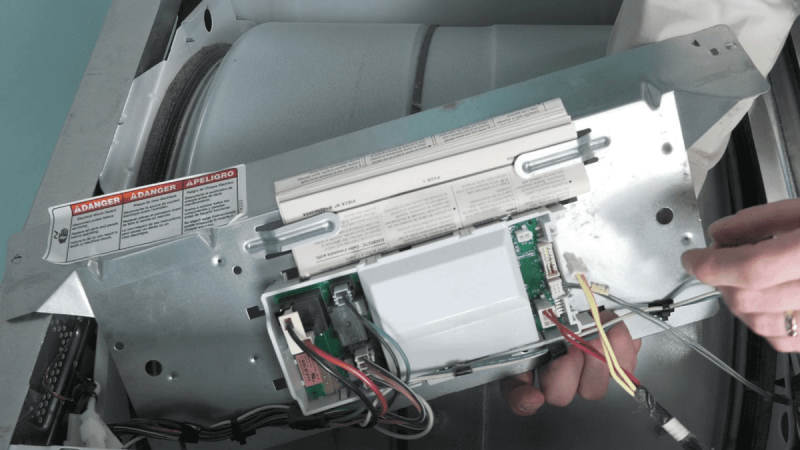

Faulty power supply

If the tumble dryer spins normally, but there is no heating inside the drum, this could indicate a problem with the input power.

The operation of electric dryers is only possible at a voltage of 240 V. This voltage level is achieved using two 120 V alternating current branches, which in total provide the required amount of power.

If only one switch is activated, no heating occurs. In this case, the drum continues to spin. You should start looking for possible problems by inspecting the circuit breaker or fuse box. For research you will need a multimeter. Using the device, check these elements for operability. In addition, it is worth checking the voltage that comes from the outlet. When working with electricity, do not forget about safety rules.

If you find problems in the form of a lack of continuity or identify problems with the fuse box or switches, you should not solve them yourself without the necessary skills and knowledge. It is better to entrust this work to an experienced electrician.

Whirlpool gas dryer does not heat up

Blown igniter

An electric current passes through the igniter, which starts the heating process in the gas dryer. Under its influence, the igniter generates enough heat to ignite the gas flame inside the burner.

Gradually, the flame heats up the air masses passing through the fan housing and entering the drum. If the igniter fails, the chain reaction will not occur and the burner will not ignite. In this case, the dryer will spin the laundry, but the air in the drum will remain cold.

If you think that the dryer has stopped heating because of a burnt igniter, then you need to find it and test this theory. Replacing a part is simple, for this you need to perform a series of actions.

- Any repair starts with de-energizing the equipment. Only after that it is necessary to pull out the screen to remove the fluff.

- Next, using a spatula, remove the spring clips located in the upper segment of the dryer.

- Lift up the top to access the door switch wires, they need to be disconnected.

- After that, you need to remove the upper part of the screws securing the front panel in order to remove it.

- If necessary, remove the bottom panel as well.

- You will have access to the pulley. Loosen it and remove the belt from it and from the motor shaft.

- Next, use the belt to lift the drum. This will give you access to the igniter, which is located on the burner tube.

- Remove the defective part by first loosening the fixing screw and disconnecting the wires.

- When installing a new element, be careful not to touch the element directly.

- Install the new part and reassemble the dryer to its original condition.

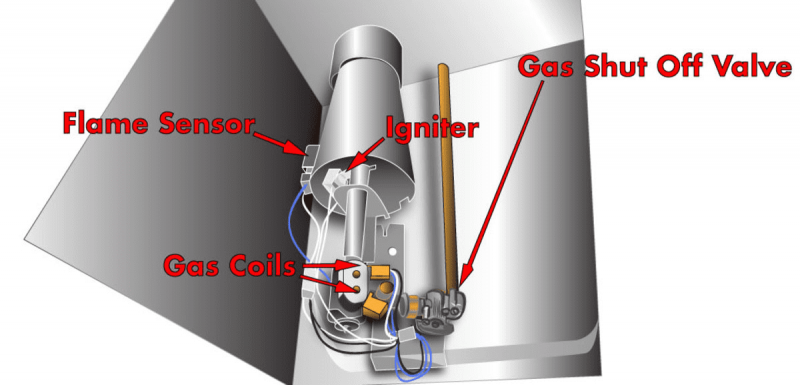

Flame sensor failed

The gas burner device requires a flame sensor. This mechanism is responsible for controlling the flame that must be inside the combustion chamber.

If the flame sensor is faulty, the flame inside the dryer will not ignite. Therefore, a broken part requires mandatory replacement. Before replacing this element, it is worth checking its continuity in order to know for sure that the failure of the dryer is caused by this very reason.

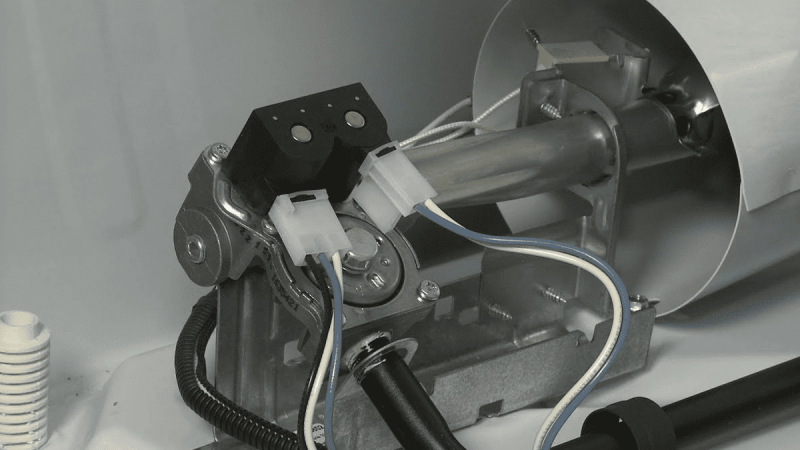

Replacing the flame sensor is easy. To begin, turn off the power to the dryer and dismantle the lint trap. Next, as in the previous version, remove the top cover and front panel. Also raise the drum, so you can get to the desired part. Disconnect all wires going to the old sensor and remove the mounting screw. Remove the element from the burner tube and replace it with a new work piece. To do this, insert the protruding end into the corresponding slot provided on the burner tube. Fasten the element with a screw. Next, install all other elements of the dryer. After assembly, conduct a test run of the device in order to check its performance.

Gas valve failure

The Whirlpool tumble dryer stops heating and also heats up only intermittently in the event of a coil failure. You can determine the problem by visually inspecting the burner. If the igniter burns for a short time, and then turns off and the gas does not ignite, then the problem is most likely a faulty gas valve.

The replacement of this valve is carried out in several stages:

- Unplug the dryer from the mains.

- Remove the lint screen.

- Remove the screws located next to the air vent.

- Remove the top with a spatula.

- Then remove the front panel.

- Push on the pulley. This manipulation will loosen the belt tension.

- Remove this belt from the pulley and also from the motor shaft.

- Use the belt to lift the drum.

- Remove the wires coming from the pair of solenoid coils and remove the mounting screw.

- Next, you need to remove the old worn gas valve coils, and install new functioning parts.

Thermal fuse not working

In the gas dryer, as well as in the electric one, there is a thermal fuse. This mechanism is responsible for preventing the dryer from overheating. Thus, the operation of the dryer becomes safe. If the thermal fuse blows and fails, the gas dryer continues to operate but does not heat up.

Damaged part must be replaced. To do this, turn off the gas and power. Then you will have to remove the back cover and disconnect all the wires going to the fuse. After loosening the fixing screw, remove the worn fuse and replace it with a new working part. Next, assemble the car in reverse order.

To prevent the fuse from blowing again, it is worth cleaning the ventilation hose.