The refusal to turn on the dryer is a big problem for the person who started washing. A malfunction can occur at the most unexpected moment. In order not to dry clothes in the old fashioned way, the user needs to quickly diagnose and fix the breakdown.

If your Whirlpool dryer refuses to start, there may be a few common problems. Usually, the incorrect behavior of the equipment during switching on is associated with a thermal fuse, switch operation, or a broken drive belt. Sometimes it’s about nutrition and you don’t have to worry about the dryer at all.

The following will describe in detail the typical problems of Whirlpool dryers, their diagnosis and solutions.

Blown fuse

Any modern technology is equipped with protective devices. The latter protect the internal components from overheating and ensure the safety of work in general.

The principle of operation of a fuse made using fusible materials is simple. The device automatically breaks the circuit if there is an overcurrent. When the protective element is deformed from heating, the contacts fastened together diverge, leading to the shutdown of the equipment.

Diagnosing such a malfunction will not be a problem. To check the operation of the thermal fuse, you need to take a multimeter and make sure that the protective device is continuous. The device is transferred to the continuity position, and the probes are located on the contacts of the switching component. If “1” is displayed on the multimeter screen, then the thermal fuse is open and it can be safely changed to a new one.

If a problem with the protective device is identified, the cost of repairing equipment will be minimal. Whirlpool tumble dryer fuses are available online for a low price.

In the case of replacing a burnt element, the user will have to inspect the ventilation holes. During operation, the dryer actively passes air through itself. Therefore, dirt often causes overheating and opening the fuse. If the holes are clogged, then the fan that creates the flow inside the machine is working in super intensive mode. Air ducts must be cleaned when clogged.

To replace the thermal fuse, the user must unplug the dryer from the mains. Failure to do so may result in electric shock.

To diagnose household appliances at home, it is enough to have a multimeter. They can check almost all components of the dryer for serviceability. Therefore, it is recommended to purchase an electrical measuring instrument as soon as possible.

Incorrect operation of switches

The dryer has several switches. They control various functions of the machine. Depending on the latter, switches can be distinguished:

- launcher;

- door;

- belt.

The start switch is designed to activate the motor and start the dryer. To check its performance, just click on the main console “Start”. If the equipment does not show signs of life, then the button is probably the cause of the malfunction.

The door switch is a security element. The device guarantees user safety during the drying cycle. If the hatch to the compartment opens, the machine stops working. In the event of a switch malfunction, the technician is not able to determine whether the door is closed, which interferes with the start-up process. The check is carried out similarly to the start switch. If the sunroof is closed and there is no click when the button is pressed, the switch must be replaced.

The process of fault diagnosis and repair in the event of failure of any of these switches will be similar. Checking is carried out using a multimeter. Each node that falls under suspicion is checked for continuity. If the switch does not work correctly, it will have to be replaced with a new one. Such a part for Whirlpool models is inexpensive and always available. The process of replacing the switch itself is not difficult.

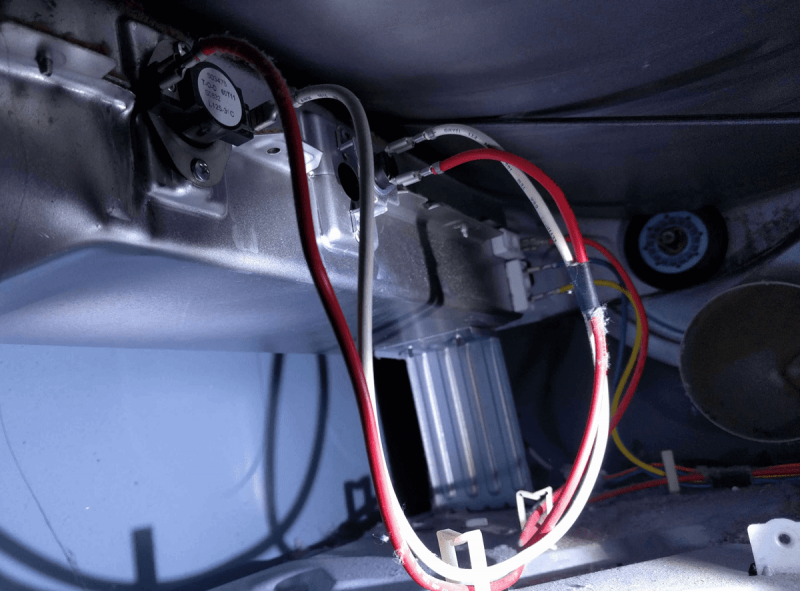

Engine malfunction

The drive unit drives the dryer components such as the drum and the fan. If the engine is faulty, then most often the fuse is the cause. Less commonly, there are problems with the switch of the dryer or the failure of the unit itself.

Engine failure is most often accompanied by jammed bearings. This is due to the wear of the elements. The bearings are initially lubricated, but over time the material dries out and friction increases. The likelihood of engine failure can be predicted by its sound. Moments indicating incorrect operation include screeching, grinding, buzzing.

Before diagnosing the unit, it is recommended to examine the thermal fuse, dryer switches and fan. Usually, the failure of these components does not allow the engine to function. If the failure of the nodes was not detected, it is worth moving on to the drive unit. The main tool in this case will be a multimeter. If the unit fails, it must be repaired or replaced. The second option is faster and more reliable, and the first one is often not financially feasible. Engine repair will not make it new, with a resource similar to the ordered part.

Broken belt

The drive belt is an important element of the dryer. It is he who is responsible for the transfer of rotation from the engine to the drum. In addition, thanks to him, the fan of the air system works.

The belt is made from durable rubber. Unfortunately, over time, the material weakens and becomes brittle. If the problem is not detected in time or overheating is missed, the part will burst. This will make it impossible to turn on the dryer.

The check is carried out by inspecting the drive belt. If it is whole and well stretched, then the cause of the malfunction is not in it. Otherwise, a replacement is required. Installation does not require special skills. Installation requires only a little effort.

Sometimes users try to invent their own drive belt using improvised means. You should not do this, since the original parts have their own specifics (size, shape, material, etc.). In addition, belts for Whirlpool models are not difficult to find.

Power problem

One of the possible reasons why the dryer does not turn on is the lack of power. In this case, the machine may be all right. It is worth starting the search for a problem with the machines located in the shield, and then moving towards the equipment, inspecting each node in the electrical wiring system.

A simple algorithm will help determine the power problem. To diagnose the network in which the dryer is involved, the user should carry out:

- Inspection of the machines in the shield. If for some reason the safety devices have worked, you need to turn them on.

- Checking the outlet. You can verify that the connector is working using another household appliance. If it works, then it’s something else.

- Inspection of the electrical part of the dryer. Sometimes the problem is inside the machine. If there are defects, they should be corrected.

Sometimes the problem may be in the wires. Establishing the integrity of the lines requires attention and time. Inspection must be carried out carefully, without missing sections. The presence of a wire break or a short in the cord may be indicated by kinks, damage to the insulation, and other external signs. You can test the integrity of the cable with a multimeter.

Faulty control board

The printed circuit board is located behind the dryer control panel. This component is the main electronic part of the machine. Although problems with electronics do not happen often, in the absence of other options, the element should be carefully examined. Incorrect operation of the board can easily lead to a complete failure of the dryer.

The check is carried out only when all other components of the machine are diagnosed for operability. In the process of studying the control, the user will need a multimeter. They can ring the tracks and make sure they are intact. However, visual inspection will help the most. The performance of the control board can be affected by oxidation, melting, swollen parts, mechanical damage. If a replacement part is available, you can make a trial replacement and verify that the removed component is in good condition.

Timer failure

The device is designed to control the execution time of all processes during the drying of laundry. Each cycle has a predetermined duration with activation according to the program. A faulty timer is a rare cause of a tumble dryer refusing to start. However, some users have come across it in practice.

Before testing the timer for performance, it is worth checking all the nodes indicated in the article. If they are in order, then you need to use a multimeter. The device checks the continuity of the timer. In the event of a malfunction, the device is replaced with a new one.