Incorrect operation of the dryer that turns off automatically is a problem that has several probable causes. Some malfunctions can be dealt with even without the experience of repairing household appliances. These, for example, include a broken wire or a malfunction of the power system. Other breakdowns will require skill from the user. The following will detail what to do if the circuit breaker trips while the dryer is running.

Dryer cut-out

Troubleshooting is the first step in problem solving. As a rule, incorrect operation of the dryer is associated with a common breakdown. Depending on the reason for the premature shutdown of the device, experts have developed clear recommendations.

Weak automaton

Often, protective devices cease to cope with the task due to prolonged use. The automata weaken and work even when the current strength is below the nominal value. To make sure that the switch is malfunctioning, you need to perform several actions:

- check the wiring for correct connection and damage;

- make sure that there are no defects on the dryer;

- check the current consumption of the machine with a device.

These steps can be carried out independently if the user has a measuring device at hand. If there is none, then you can call an electrician to inspect the machine. If the switch is defective, replace it with a new one. The problem is especially relevant for old houses.

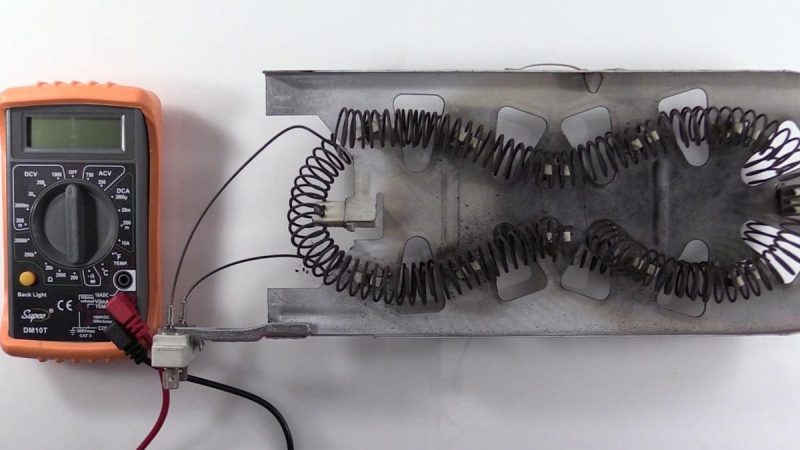

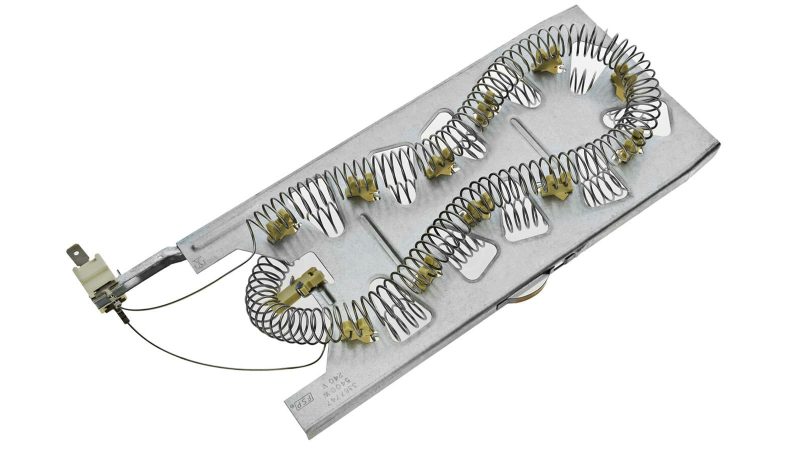

Breakage of the heating element, block

Failure of the heating element in the dryer leads to a short circuit. A short circuit to the device case, in turn, leads to the operation of the circuit breaker. Checking for such a malfunction will require skills in using a multimeter. Using the device, the user will have to examine the part for a short circuit. If the assumption is confirmed, then the heating element will have to be replaced with a new one.

Also a common malfunction is the breakdown of the heating element unit. It is checked similarly to the heating element. If there is a short, the part needs to be replaced.

Internal closure

The cause of the malfunction, not related to the operability of the heating element and the block, may lie in the failure of other elements of the device. Often the machine is triggered as a result of an internal circuit. The latter may be the result of a breakdown:

- door switch;

- engine;

- timer;

- on/off switch.

Checking each element of the dryer is carried out using an ohmmeter. The user must determine if there is a short circuit in one of the machine nodes. If this is the case, then a damaged component is the likely cause of the switch tripping. It can be replaced or repaired.

Terminal block

The block is used to connect electrical cords. In the process of diagnosing a malfunction, the user will have to inspect each wire for defects (burnt insulation, cracks, breaks) and connection quality. Sometimes, this fault will form an arc that damages the power supply.

Engine

When the drive element fails, it causes a short circuit. The check is carried out in the same way as other elements of the dryer. Using a multimeter, the presence of a short circuit on the windings is checked. After confirming the malfunction, the engine must be replaced.

The main reason for engine failure is the regular overload of equipment during operation. Extreme operating modes lead to rapid wear of the main components. In order not to encounter a similar problem between each new load, you need to let the dryer rest. 40-60 minutes is enough for a break.

The dryer runs for 10 minutes before the machine switches off

Sometimes the dryer may operate for a while before the switch is flipped off. Usually the machine is activated after ten minutes. The reason for the shutdown may be both the incorrect operation of the protective device and the malfunction of the household appliance.

Insufficient denomination

Sometimes the switch is too weak to function correctly. The machine must correspond to the nominal value of 30 amperes. During the test, you will need to measure the current strength with the dryer turned on. For this, an ammeter is used. If the diagnostics showed a value higher than the rating of the circuit breaker, then the latter was selected incorrectly and should be replaced.

Checking the heating element

The second malfunction may be a breakdown of the heating element. To check the part, it is enough to connect the multimeter probes to the terminals of the heating element. The resistance is to be measured, so the appropriate mode must be selected on the device. The normal value is in the range of 7.8-11.8 ohms. If a deviation is obtained as a result, then the heating element is probably defective.

The problem with turning off the machine at the dryer LG

If the machine shuts down due to the operation of the circuit breaker, then the diagnosis should be carried out in the order described above. Typically, owners of LG dryers are faced with incorrect wiring or damage to the braid. Otherwise, the standard faults are similar to other dryers. To check at hand, the user must have a multimeter (ohmmeter) and an ammeter. With the help of devices, resistance, current strength and wire breakage are checked. However, at the very beginning it is worth studying the information from the user manual supplied with the model.

The tumble dryer must be connected to a waterproof socket with solid insulation wire. It is not recommended to use extension cords (tees) that increase the load on the wiring.

Whirlpool dryer triggers circuit breaker

Troubleshooting Whirlpool machines, as in the case of LG-branded appliances, requires familiarization with the manual. The document will allow you to understand the correct connection of the dryer and save time looking for typical breakdowns. The most common problems in which the machine turns off Whirlpool appliances are:

- Faulty circuit breaker (switch is weak or broken).

- Damage to the power cord. Sometimes the wires can break off or connect poorly. To make sure the cord is in good condition, you need to carefully examine it. If damage is visible (cracks, kinks, exposed wiring), replacement is required.

- Excessive load. Causes equipment to overheat. The user is advised to use the tumble dryer at the highest heat setting with caution.

- Power surge. It may not affect the performance of the dryer in any way. To restore the operating mode, you need to turn on the machine.

- Broken outlet. Diagnosed with the help of other household appliances.

When a malfunction occurs, do not panic. Any damage is repaired. Depending on the diagnostic results, the user can either repair or replace the failed assembly. If it is not possible to cope with the task on their own, the user is advised to contact an electrician.