Samsung is a leading manufacturer of home appliances. At the same time, even such giants are not immune from failures. Tumble dryers manufactured by Samsung sometimes fail. In this article, we will take a closer look at common breakdowns, describe diagnostic methods and options for eliminating identified problems.

Common breakdowns of Samsung dryers

The heating element has failed

The first place in the ranking of problems is the breakdown of the heating element. During operation, this part may burn out. Most often, it occurs in the third or fifth year of using the equipment. The heating element is one of the key parts of the entire mechanism. It generates heat, thanks to which the laundry loaded into the drum dries. Without it, the dryer simply will not be able to perform its direct function.

Therefore, do not postpone repairs. First of all, it is necessary to remove the heating element from the dryer and carry out a visual inspection. Inspect the coils for damage and lack of ground. If they are detected, then the heating element is out of order.

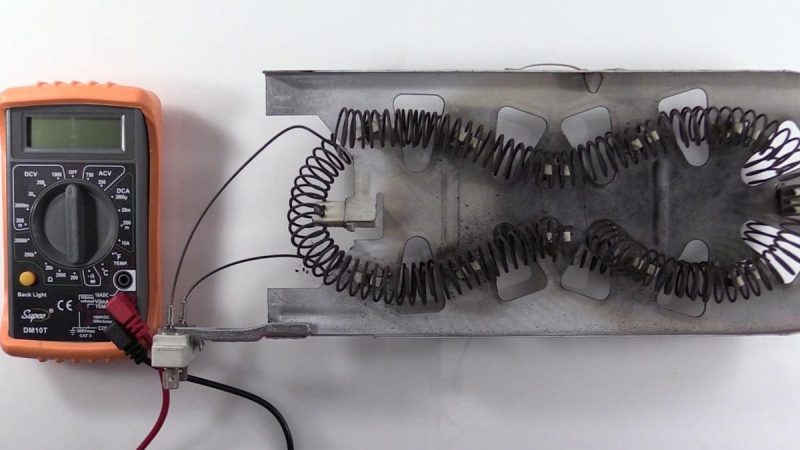

One thing to keep in mind is that a burnt-out heating element is unlikely to be seen with a simple inspection. This is where a multimeter comes in handy. The device will be needed to check the continuity of the coils. Coils of non-permanent type are subject to burnout. It’s pretty easy to check them yourself. The measuring device must be connected directly to the heating element.

If the display of the multimeter shows indicators of about 10 ohms, we can talk about the health of the element. If there is no resistance, then the part is not working properly. If problems are found, the heating element must be replaced.

Almost anyone can cope with the replacement, you need to purchase a new heating element and put it in place of the burned out one. In addition, you can always call the master who will help with the replacement.

The thermal fuse is broken

This error is also quite common. In Samsung dryers, the fuse often blows. This problem cannot be ignored. The thermal fuse is required to detect the temperature level inside the dryer. It performs a fire prevention function. Therefore, it is necessary to immediately address the problem after the discovery of the problem.

A blown thermal fuse is indicated by the fact that the dryer stops heating at all. The fact is that manufacturers have taken care of the safety of users of these household appliances in advance. Modern models do not heat up in the event of a thermal fuse failure. To identify a blown thermal fuse in a Samsung dryer, you need to follow a few steps:

- First of all, you must disconnect the electrical appliance from the mains. This way you will prevent the risk of an accident. This rule applies to the repair of any household appliances.

- After that, you can start searching for the fuse. To do this, carefully read the instructions that came with the dryer, or find the user manual on the Internet.

- Using a multimeter, you can determine if the fuse is good or bad.

If you are convinced that the problem of the dryer malfunction lies in a blown fuse, then it needs to be changed.

Noisy drum rollers

In some cases, the drum rollers begin to rattle. An unpleasant sound indicates that the part is worn out and needs to be replaced. A damaged roller prevents the drum from spinning normally, which is why a characteristic rattle appears.

To check, you will have to disassemble the dryer. It is necessary to dismantle the top and front covers, take the partitions and remove the drum. Only in this way you can get to the rollers.

It will be enough to conduct a visual inspection, which will determine the condition of the parts. If one roller is damaged, it is recommended to replace the entire set at once. This will avoid repeated repairs that may be needed soon.

Idler pulley failed

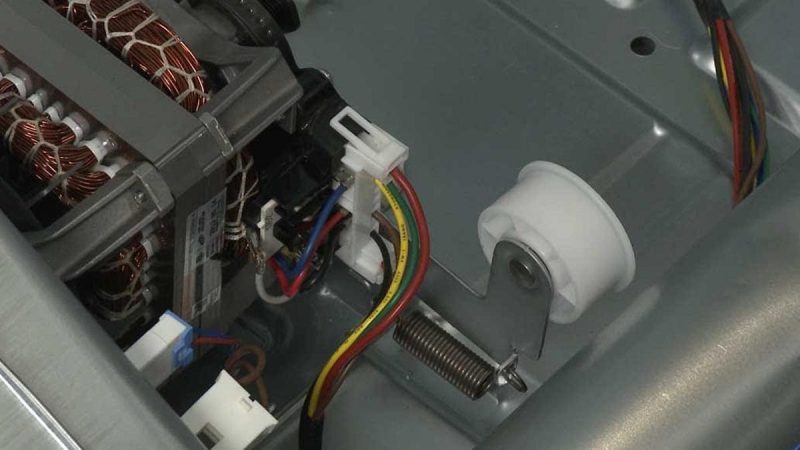

And owners of Samsung dryers may face this problem. This is a roller that keeps the drum belt taut. If the rollers are broken, then the dryer starts to creak, and sometimes stops working altogether.

During the repair, it is necessary to remove the plug from the dryer and remove the top panel. You will also have to dismantle the front cover. After that, tilt the dryer forward so that the drum moves away and you have a view of the pulley. Next, you need to evaluate the performance of the spring mechanism and check the bearing. If the bearing turns with difficulty, then you can try to lubricate it. However, if these actions did not bring the desired result, then the worn part will need to be changed. To do this, remove it with pliers and replace it with a new pulley. After that, assemble all previously dismantled elements in reverse order.

Blocking the motor relay of the control board in the activation position

The tumble dryer starts to malfunction because the motor relay on the control board for some reason does not switch from the on position. In this case, the dryer continues to run until you open the door. In some cases, the machine must be disconnected from the network.

The solution to the problem is to replace the control board. This procedure will require the removal of the top cover. To do this, unscrew the retaining screws and remove the panel. This way you will get to the faulty board. Remove all the wires going to it, and then proceed to dismantle. After that, place the new board in the corresponding tabs and connect it to the system with wires. Replace the cover and carry out a test run.