Absolutely all washing machines make a sound during operation, this is quite normal. But there are several types of noise that are strictly unacceptable. These include a loud screech when mixing. For what reason does it appear, and what to do?

So, if the machine squeals as part of the mixing cycle, you need to make sure that it is not overloaded and that nothing is stuck under the mixer. After eliminating these moments, you can remove worn drive belts, pulleys that have been damaged or covered with dirt, a broken clutch assembly located in the gearbox.

Sometimes, in order to remove unwanted creak, you need to spend a lot of time and effort. However, you should not worry, because this instruction will consider the most common causes of its formation, as well as ways to get rid of the problem.

Once the owner has noticed a creaking sound coming from this piece of household appliances, there are a few things to pay attention to. They will be considered in the material in turn.

-

The washing machine is simply overloaded

Finding the root cause of such an unpleasant sound can hypothetically lead to frustration and cause a lot of difficulties. So the first step is to check for problems that can be easily eliminated immediately. For example, you should ask yourself if there is too much laundry in the drum. After all, in this case, he will take on a significant load, which will lead to rapid wear of such elements as belts, pulleys, and so on.

As a result, as you might guess, the machine will start to make strange sounds, including a creak during mixing. It is necessary to understand how to avoid a strong overload of the unit. First you need to check the instruction manual. The manufacturer must indicate in it information about what weight is safe.

Even if you don’t have this information, it’s a good rule of thumb to follow a basic rule of thumb: load clothing at a minimum density so that it doesn’t exceed 2/3 of the maximum capacity mark. Anything more is fraught with negative consequences.

-

Object stuck in the agitator

As soon as the steps from the first paragraph are completed, you need to take a closer look at the mixer. In particular, it is worth noting that it does not act as part of the drum. Instead, it is a piece attached by manufacturers to the back or bottom with a bolt. As a result, a tiny gap is formed between the bottom of this element and the surface of the drum.

How to do it in practice? Many agitators have a lid that covers the top. It is logical to assume that it must be removed to open the internal chamber of the agitator. Once this can be done, it will be necessary to use a ratchet with an extension in order to get inside. The main goal is to unscrew the bolt at the very bottom. After the agitator is removed, it will not be difficult to free any stuck object from it.

-

Belt wear

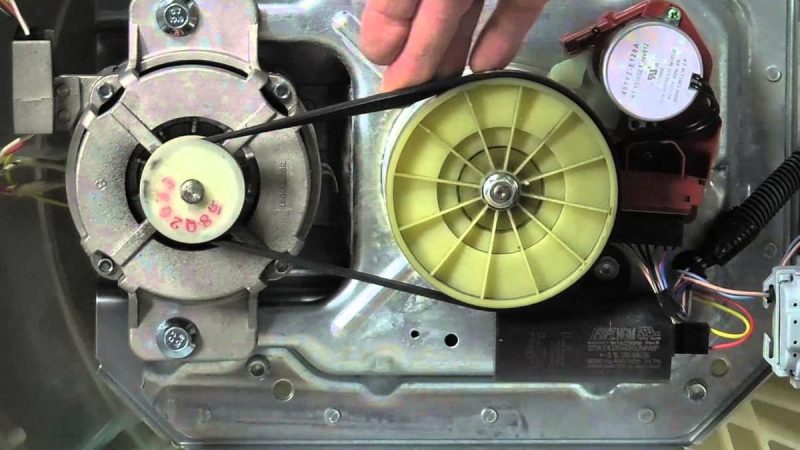

The actuation of so many machines today takes place using belts. As part of the energy generation by the motor, they rotate, as a result, the resource is transferred to the drum, and it begins to rotate. Manufacturers usually make these elements from black rubber. This material is used to create tires. The belt runs through pulleys and tensioners to ensure a tight fit to the motor and any rotating component.

However, over time the belt is subject to wear and this is normal. As a result, it becomes loose, torn and, of course, wears out. As a result, it loses grip and begins to creak strongly. At this point, it needs to be replaced. This process is quite simple. You just need to get access to it as part of removing the back panel. After that, you need to press the tension element and put the corrugated side inward.

-

Dirt in pulleys or damage

Traditionally, the belt passes through this element or even through several pieces. It is this process that helps maintain tension and align the belt. Unfortunately, the pulley squeaks as it gets dirty and wears out naturally. To find out that this is really the case, you need to remove the elements from the device. Before getting down to business, you need to start by removing the drive belt, just as mentioned in the third paragraph.

The procedure is generally simple and clear. It is advisable to unscrew the bolt holding the system in place. Once this is done, it may be necessary to shake the pulley a little to remove it from the shaft. After that, it is necessary to inspect for dirt and all kinds of damage. After all, they can lead to a creak. The pulley requires thorough cleaning in case it is dirty, as well as replacement with a new element if damaged.

-

Deterioration of the clutch assembly

Of course, that might be the issue. The clutch is always responsible for the movements of the tank and agitator in this system. As the assembly wears out, it provokes the appearance of a squeak during mixing. This is an important part of the gearbox in any washing machine.

A system change is required. First you need to remove the gearbox to replace the clutch assembly, this task is not easy to cope with, since the component is huge in terms of its size. You may need an assistant to assist in the process of transporting the element. Then you need to remove the thrust washer and the clutch support ring to release it. Once this can be done, you can install a new mechanism.

FAQ

It is not uncommon for owners of automatic washing machines to face similar but different problems. Accordingly, they often ask certain questions. Below are detailed answers to them.

What is the stir cycle during the operation of the washing machine?

This is one of the significant parts of the classic washing program. In this case, the stirrer turns several times from one side to the other. As a result, the unit separates any dirt from the laundry that is being washed, which guarantees the efficiency of the process. Actually, it is on this principle that such installations of such a plan work.

How do I know about shaking in my washing machine?

It is not difficult to do this, because in this case it moves back and forth. As this process continues, the user will see that the water, while mixing the clothes with it and the washing powder, becomes as dirty as possible. If this does not happen, perhaps everything is fine, and nothing needs to be done. However, in practice, most often it is these “symptoms” that indicate the existence of problems.

What sounds are considered normal?

When the device is functioning, it emits an electrical hum at most, or the user hears a grinding sound. You can also hear a pulse or a sound that simulates a waterfall when the device turns on the recirculation pump. If there are any deviations, it is worth checking each item described in this manual, it is possible that there have been breakdowns in the system that require elimination.

How to understand if the mixer is broken?

The absence of any movement is traditionally a sure sign. Traditionally, the agitator rotates back and forth repeatedly during this cycle. Although sometimes other uncharacteristic movements may appear, which should alert and force you to check the operation of the system.

Should the stirrer itself be loosened?

On modern devices, you can find that it is really weakened, and this is a fact. It is connected, first of all, with the fact that manufacturers deliberately design it in such a way that there are small fluctuations, and more or less high-quality protection against damage is provided. However, in any case, it is worth checking the reliability of the agitator bolt in order to avoid swinging.