The Bosch brand is well known as one of the most reliable and high-quality manufacturers of household appliances, including dishwashers. But even such reliable devices sometimes fail. And in this case, it is important to identify the malfunction and eliminate it promptly.

Our small guide on the TOP 5 most common problems with Bosch dishwashers will help with this.

Spontaneous filling with clean water

The most common problem with almost all models of dishwashers of this brand is filling with clean water when the power is off. This is quite a nuisance problem, as the set of water can be fast enough to flood the kitchen or damage units that come into contact with the water.

In most cases, the cause of this malfunction is a stuck inlet valve locked in the open position. In this case, a large stream of water can enter the main compartment, which houses the baskets for dishes. This is possible when the dishwasher is switched off.

Often such a malfunction occurs due to damage to the solenoid (inductor) by hard tap water. At the same time, a characteristic white coating can be observed on the surface of the intake valve.

The solution to the problem is to completely replace the valve. Repair of this element is irrational and almost never carried out.

Filling the main compartment with dirty water

The second most common problem that occurs when operating Bosch dishwashers is filling the main compartment with dirty sewage. In addition to the previously mentioned damage to the structural elements of the device, this also creates unsanitary conditions inside the operating room, which can be hazardous to health.

This situation often occurs due to damage to the check valve. In the normal state, this element ensures the movement of wastewater in only one direction, but in the event of a malfunction, it ceases to cope with this function.

Depending on the model of the dishwasher, this element is located either inside the drain pump housing, or directly in the main compartment. Luckily, it’s easy to replace with a few simple steps:

- Open the dishwasher door and remove the lower basket.

- Move the drain hose away for better access to the screen filter.

- Loosen the screws securing the housing cover to the screen filter to gain access to the check valve.

- Remove the check valve (which is also fixed with a few bolts) and install a new one.

- Check that the valve is firmly fixed in place.

- Reinstall the previously removed parts of the dishwasher.

This elementary repair procedure can be carried out at home, even without much experience in such procedures.

Wrong water drain

Visually, this is observed as the accumulation of a relatively small amount of sewage at the bottom of the main compartment. This has an extremely negative effect on the hygienic condition of the device, and therefore such a problem must be eliminated as quickly as possible.

But this is easy to fix at home. First you need to remove the external filter and drain. If there is a presence of sewage that has not gone away, then before this, the inner case must be thoroughly wiped.

Next, you need to unscrew a few bolts that secure the cover of the dehumidifier pump housing in order to gain access to the impeller (impeller) – a helical element resembling a propeller. Incomplete drying just arises from a violation of the operation of this element. Inspect the impeller and remove debris that prevents it from scrolling normally. Wipe the impeller thoroughly with a dry cloth. Additionally, it is recommended to remove the rubber inlet valve located nearby, rinse it with water and also wipe it with a rag until completely dry.

After removing the blockage, it is necessary to return all disassembled parts to their place and conduct a test run of the dishwasher.

Incomplete filling of the main compartment with water

The fourth malfunction on our list is the incomplete filling of the dishwasher with water or even the complete absence of water flow. Unlike previous problems, this can cause the device to become completely unusable. Also, if the dishes are not completely filled with water, the dishes are not washed thoroughly enough and a bacterial infection may remain on them.

As in the case of involuntary filling of the machine with clean water, the cause of such a malfunction is most likely a malfunction of the inlet valve. The mechanism for this dysfunction is that the valve closes too quickly when starting the dishwasher cycle.

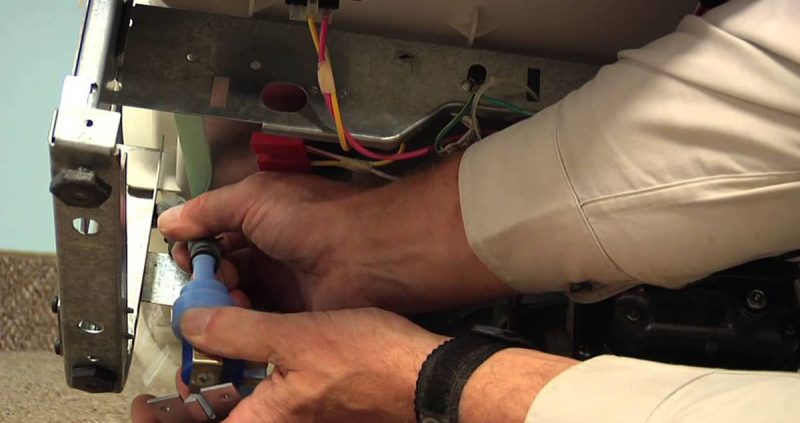

Such a malfunction is eliminated by replacing the water supply valve (inlet valve). It can be accessed through the bottom panel of the dishwasher. After removing the bottom panel, it is necessary to disconnect the electrical wiring, disconnect the drain pipe and unscrew the connecting elbow (most often made of brass).

After dismantling the faulty valve and installing a new one, it is necessary to return all dismantled elements to their original state. To check the correct installation, it is recommended to test run the dishwasher.

As an additional diagnostic of a newly installed valve, a solenoids test can serve. The fact is that even in new valves, these elements may not work correctly. Solenoids are a system of several magnets that open and close the intake valve under the influence of an electric current. The normal operation of the solenoids can be determined by their electrical voltage, which is checked with a multimeter.

Incomplete drying

The final problem with Bosch dishwashers is the incomplete drying of the plates after the end of the work cycle. Different models have an excellent drying mechanism. It may be based on the operation of ventilation with a motor or a heating device.

If the model works with ventilation, then the cause of the malfunction is most likely in the ventilation valve. Its full closing and opening can be checked manually. If no problems are found with this element, then the problem may be a motor breakdown. You can also check the correct operation of the ventilation motor using a multimeter. In case of detection of insufficient voltage or defects in the ventilation blades, these elements must be replaced with new ones.

Heating elements are used in models with a heating drying system. It is not possible to visually determine dysfunction, so a multimeter will also help here.

In both described cases, replacing the elements of the drying system is a rather complex and time-consuming task. Therefore, it is not recommended to carry out such repairs at home.