There are many reasons a Fisher Paykel tumble dryer does not heat up. Before you panic and call the wizard, you can diagnose yourself. If you find minor faults, you can fix them yourself and save your family budget. Let’s talk about the most popular reasons for the lack of heating of the Fisher Paykel dryer and how to eliminate them.

Several faults in the dryer that are not malfunctions

If the Fisher Paykel dryer does not heat up, it does not necessarily mean that some component is out of order. Before you panic, follow these initial troubleshooting steps to rule out some underlying issues.

- First, check the selected drying cycle. Popular drying cycles such as Cool Air or Air Dry do not require heating. If you have selected these cycles, the appliance will not heat up. When the Paykel dryer detects that the inside of the garment is dry, it goes into the cooling or airing phase. The dryer will cool down at this point in the drying cycle instead of generating more heat.

- Drain the water tank. Condenser dryer models are equipped with a water tank that collects all the moisture removed from the garment in the drum. When the tank is full, the dryer no longer generates heat. To fix this, all you have to do is empty the water tank. In the future, you need to monitor the filling of the tank and remove water from it in time.

- Check the ventilation holes. Make sure they are free of dust and other contaminants: clogged ventilation holes in the dryer can cause it to overheat. As a result, the dryer will no longer generate heat to protect itself from further overheating. If there are pets in the house that often shed, you will need to clean the ventilation more often.

Important: Always disconnect the dryer from the power source before opening the tumble dryer for troubleshooting or repair. If it is a gas dryer, turn off the gas supply as well. Doing so will prevent electrical shock and reduce the risk of injury while using the instrument. If you are unsure when performing any repairs, always consult a qualified technician.

Blown fuse or tripped switch

If the dryer is plugged into an outlet, its power supply is protected by a fuse. In the case of direct connection to the panel, there must be a circuit breaker. These devices serve the same purpose: turn off the power to the dryer when necessary so that the dryer does not create a risk of fire.

Each of these protective devices works in its own way: the fuse will burn out completely and need to be replaced, and the machine will work and turn off – you just have to turn it on again.

Remember that a blown fuse or tripped switch is a symptom, not necessarily the root cause. Therefore, if these parts fail repeatedly, you need to troubleshoot the electrical part of the dryer. Also, the problem may be in the wrong power supply and power failure.

Fuses and circuit breakers are designed to trip when an electrical fault occurs. For example, if a tumble dryer is short-circuited and consumes too much power, a fuse or circuit breaker will trip. In doing so, these devices break the circuit and prevent electricity from entering some parts of the dryer.

If the fuse is blown, it must be replaced. However, a tripped switch can simply be turned back on.

As mentioned earlier, these problems are symptoms, not the root cause. Therefore, if they continue to occur even after the fault has been rectified, the dryer should be checked for electrical faults such as short circuits.

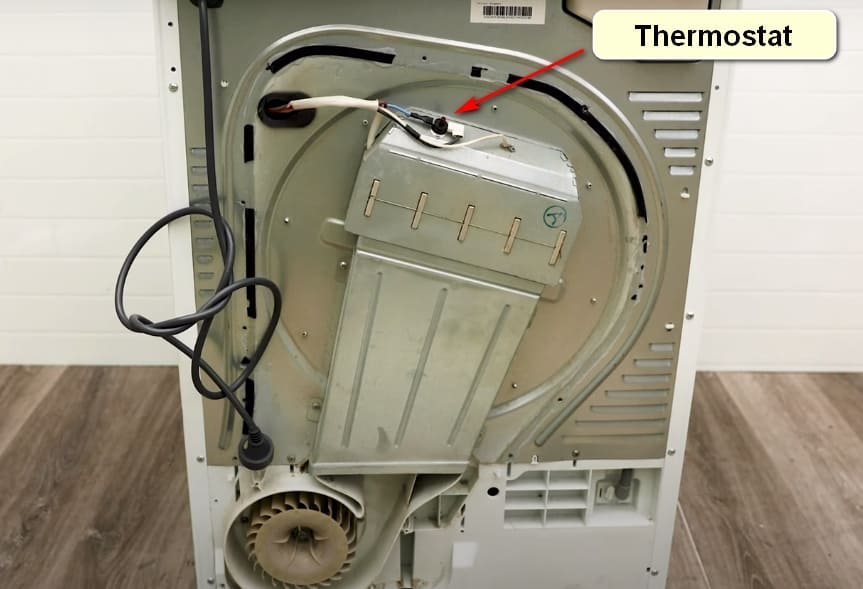

High limit thermostat problem

The High Limit Thermostat is a safety device that protects your Fisher Paykel from overheating. It is usually located next to the blower housing, from where the hot air enters the dryer drum. It is essentially a switch that is temperature activated. Therefore, when he discovers that the temperature inside the dryer is too high, he breaks the electrical circuit of the device and prevents it from continuing to heat up. In doing so, the thermostat reduces the overall fire hazard posed by the dryer.

If the thermostat is working properly, it will only break the electrical circuit when the dryer gets too hot. However, a faulty thermostat will mistakenly do this and prevent the dryer from heating up at all, even if necessary.

Why does your tumble dryer get hot when it is not running? Due to a malfunctioning thermostat, although the rest of the dryer is working properly, the heating element is not receiving energy and cannot generate heat.

To fix this, the thermostat needs to be replaced. To gain access to the thermostat, the rear panel of the dryer must be removed. If you cannot find the thermostat, then refer to the user manual for detailed diagrams and instructions on how to easily repair the dryer.

Next, you need to disconnect the electrical connector attached to it. Then unscrew the screws that hold it in place to remove the thermostat. This will allow you to install a new thermostat and reconnect the electrical wires to it. After repairs, make sure the dryer is operating normally.

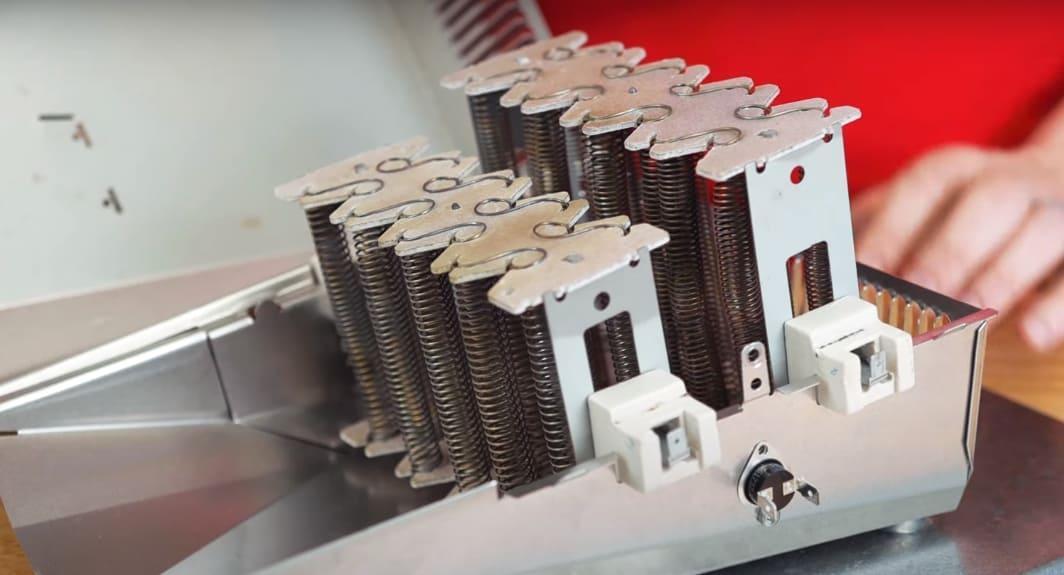

Defective heating element

The heating element in the tumble dryer is one of the most important parts. It is responsible for raising the temperature sufficient to effectively dry clothes. The heating element consists of a metal part and wires that conduct electricity and also provide great resistance. When power is applied to the heating element, the wires heat up very quickly. A fan will then blow all that heat through the drum to remove moisture from the inside of the laundry.

Heating elements wear out due to constant heating and cooling. At some point, the heating element can burn out or break, preventing the machine from generating heat when needed.

The easiest way to repair a failed heating element is to completely replace it. This requires access to the heating element housing through the rear of the dryer.

If you are unsure where the heating element is located and what it looks like, refer to the user manual or datasheet. These documents will indicate the heating element for your dryer model.

Next, disconnect the electrical connectors attached to it.

Then remove any mounting screws or bolts holding it in place. Unscrew the screws completely to remove the faulty heater. Then insert a new heating element and secure it in place. Then replace the electrical connectors as before and close the rear panel of the dryer.

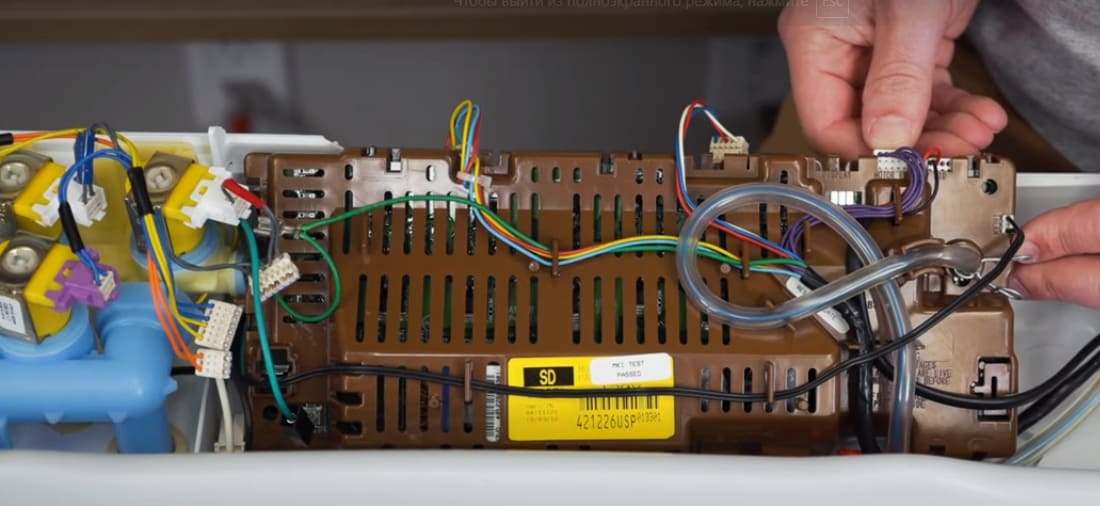

Defective engine control module

The motor control module is responsible for powering two components: the dryer motor and its heating elements. It will activate one or both of these parts, depending on which stage of the drying cycle is currently taking place in the appliance.

A defective ECM can result in the motor or heating elements not receiving power. This problem can be caused by electrical damage or general wear and tear.

Electrical damage, such as a power surge during a thunderstorm, can damage the ECM and prevent it from powering the dryer heating elements.

In addition, the longer the dryer has been used, the greater the likelihood of wear and tear, due to which the control module may also not power the heating elements.

To correct this problem, it is necessary to replace the failed engine control module. In the Paykel dryer, you will find the motor control module in the lower left corner of the appliance. To access it, you first need to remove the front cover of the dryer.

The ECM has a top cover that can be removed by pressing the release tab. This will allow you to disconnect the electrical wires connected to the module.

Tip: To avoid confusion in the wiring diagram, take a photo with your mobile phone before disconnecting. This image will serve as a useful guide later when you need to reconnect the wires.

Disconnect the electrical wires first, then remove the screw holding the module in place. At this point, you should be able to easily remove the entire module. Then insert the new ECM in its place.

Secure the module by replacing the screw you removed earlier and then also start reconnecting all electrical wires.

Finally, install the top cover of the motor control module and then install the front panel of the dryer.

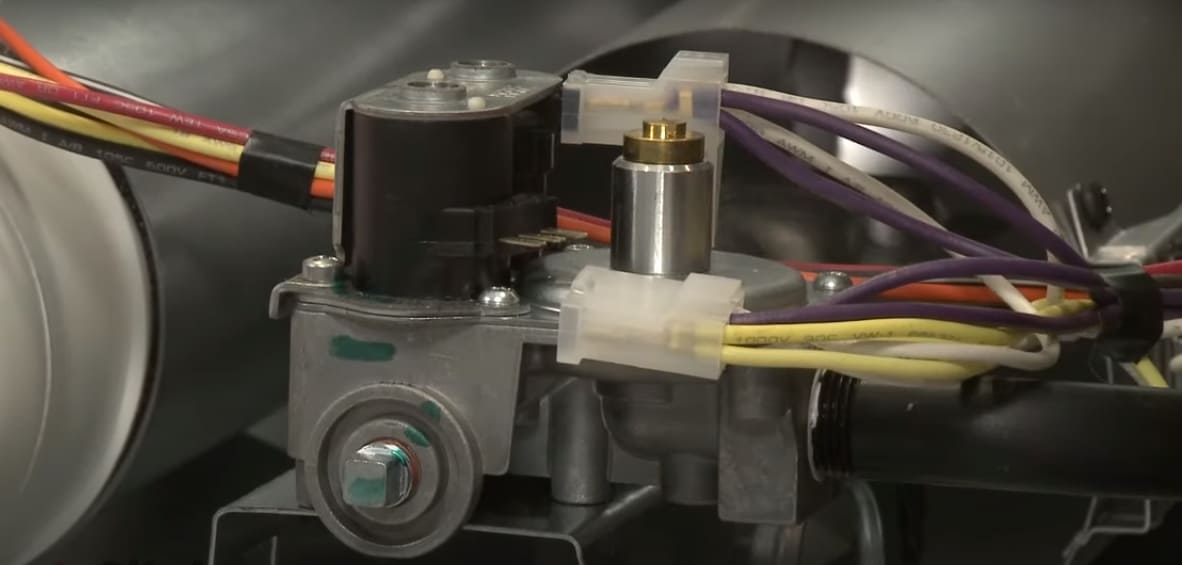

Other problems in which the tumble dryer does not heat up

Gas dryers have a problem with the gas valve solenoid. This device must automatically open the gas valve for gas to flow. If the solenoid is damaged, the burner will constantly shut down and the dryer will not heat up. At the same time, you should always check the performance of the igniter – if it is serviceable, then the solenoids are changed, or the entire system is completely changed. If the igniter is glowing and working properly, then only the solenoids should be replaced.

The operation of the igniter is also checked with a multimeter and, in the event of a malfunction, the part is replaced with a new one.

On gas dryers, the flame sensor may deteriorate. This part is designed to detect heat from the flame and if the sensor is damaged, the dryer will not heat up. To check the performance of the fire sensor, a multimeter is used and in case of damage detected, the sensor is replaced with a new one.

The cycle thermostat, unlike the high limit thermostat, rarely breaks. Still, if all other parts are in order, it is worth checking it with a multimeter.

Sometimes the timer breaks in dryers. In this case, the tumble dryer will not heat up. If there is a suspicion of a timer malfunction, then you should check it with a multimeter and replace it if a breakdown is found.

Most failures in Fisher Paykel dryers when there is no heat are easy to fix yourself. It is necessary to identify the problem and replace the worn out parts with new ones. Simple DIY repairs will save your family budget and extend the life of your dryer.