Washing machines of the latest generation are complex devices with a large number of elements that can theoretically break down. For the convenience of users in identifying defects and breakdowns in the mechanism, and electronics of the washing machine, the ability to display the error that has occurred is made in advance in the work program of most units. It is important to be able to recognize the code that appears on the display in order to subsequently understand the condition of the machine and its ability to work.

The washing machine displays an erroneous action on the display, indicating a problem with the design of the lock, a breakdown of the locking system. When the door is slammed more than once and the attempts are unsuccessful, such an error code will appear on the display of the washing machine.

Why does the error occur

The experience of appliance repair specialists has shown seven reasons why an error appears on the display of the washing machine. The encouraging fact in such a situation is that most of the circumstances are not related to equipment malfunction and can be quickly eliminated. More detailed consideration is required for common malfunctions that impede the operation of the device.

The door is not fully closed

With all the evidence, sometimes such a flaw can not be immediately noticed, but it happens to almost every user. At a door with loose pressing, the latch does not hold in the well. If you try to start washing in this situation, a warning message will light up.

To enable a successful start of the device, you need to check how correctly and tightly the lock is closed. This can be understood by the characteristic sound at the end of operation. You need to listen to him when closing always.

Sedimentation of detergents on the details of the lock

Particles of washing powder can gradually accumulate, most often when an excess amount of detergent is poured into the washing equipment. These residues will constantly accumulate on the surfaces of the unit, without periodic washing, the deposits will disable the device.

Settling of particles on the shutter mechanism prevents full closing. Such a precipitate is formed not only from the powder, but also from other household chemicals for washing, boiling clothes: bleaches, rinses, stain removers.

To resolve this issue, you need to inspect the latch, check if there is a settled raid on it. If required, you need to rinse with a damp cloth wherever it appeared, especially in places where adjacent parts come into contact.

Weight overload

Often a common cause that can go unnoticed, and for its simplicity, it is forgotten. If the drum is stuffed to capacity with linen, then it will not fully latch the locking device on the door.

In addition, an overloaded machine works less efficiently, does not wash all the dirt in the normal mode. It is necessary to fill the drum with laundry for the weight calculated by the manufacturer, as written in the user manual.

The fact of overload can be established during washing if the items are made of hygroscopic material that absorbs a lot of moisture. The tank will be full of contents, and the machine will give an error. To eliminate, you need to pull out some things and continue the wash cycle. If this was the reason, then fill the washing machine correctly the next time you load the tank.

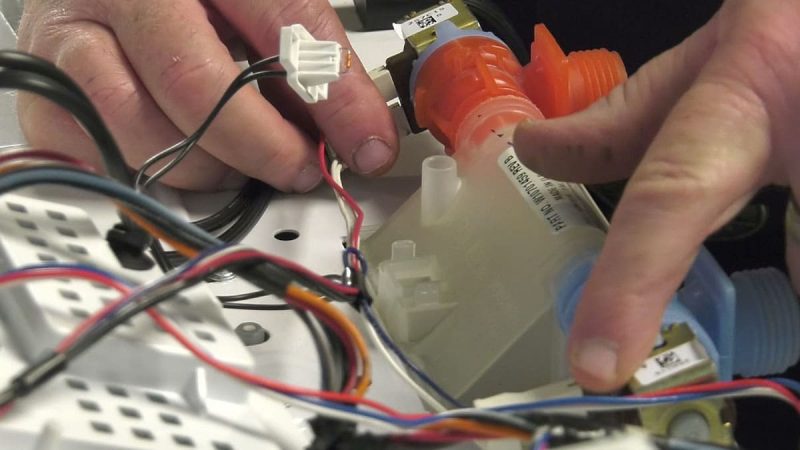

Poor quality wiring

A washing machine is an electrical appliance equipped with connecting elements. They conduct electrical current to various parts of the device. If one connecting node breaks, full closing is impossible, and the device itself will be washed properly.

To check the quality of electrical contacts, you need to find out if there are any defects on the internal wiring. All wires with broken insulation are considered faulty. You can also see:

- Melted areas;

- Burnt insulation;

- Bare veins;

- Wire breaks.

Such damage must be repaired or replaced. After troubleshooting, check that the faulty wires were the source of the error on the scoreboard.

Control unit not working

The device of the machine includes a node in the form of a printed circuit board, which coordinates many functions, includes the correct interaction of components. Breakdown of the printed circuit board occurs infrequently, but if it does, then the unit malfunctions, and the system writes an erroneous result.

It is possible to assume a marriage of the main board and consider that the failure occurred due to it, only by the method of elimination, when other possibilities have been exhausted. To check the suitability of this module, you need to remove the part of the housing under which access is provided. The performance is checked with a multimeter. If the measurement showed a malfunction of this element, then it must be removed and a new one installed.

Hatch latch assembly failure

If a visual inspection showed that there is no settling of detergent particles on the latch, the door fits snugly, the machine is not overloaded with laundry, then the locking hook itself can be assumed to be broken. The sunroof lock device consists of several plastic parts that can wear out over time.

Do not use physical force when using the access door. This will break the plastic parts, fasteners, handles. Do not allow children to play with the hatch door, locking mechanism. This will not only lead to damage, but threatens the risk of injury. Do not hang wet laundry on the open hatch. The mechanism will not withstand heavy loads.

Worn out from years of use, the hook stops holding. Replaced with a replacement. The replacement event itself is not easy to perform. Here is a special explanation of how to do it yourself and how to make further settings.

Sunroof latch assembly replacement

The process of installing a new latch is laborious when compared to the troubleshooting steps described earlier. You can replace it yourself, without professional experience, but you must strictly follow the sequence.

Before starting repair work, observing safety rules, it is necessary to disconnect the unit from the socket. After a power outage, an algorithm of actions is performed that allows you to replace the hatch blocking device on a side-loading machine:

- Loosen the doorway rubber seal. It is held in place by a clamping device that runs along the contour of the seal. It is more convenient to do this with round nose pliers.

- After bending the holder, the seal along the edge of the hatch opening can be easily removed. But you don’t need to disconnect it all, you just need to bend the section next to the locking latch.

- Loosen the screws on the front that secure the assembly. This will come in handy with a screwdriver with a slot size of 20 mm, prepare it for convenience in advance.

- After dismantling the screw fastener, it is necessary to disconnect the harness from the wires connecting the door latch block with the rest of the device mechanisms. Now the knot will be removed completely.

- Connect the new replacement latch to the wiring harness, then put the entire unit in its original position and tighten the screws.

- Fit the boot lip seal flat, install the new clip and align it.

- Plug in the machine and check the functionality of the new parts.

Update settings, reboot

To correct the error, experts recommend deleting the unit settings and checking the result of this step. There are two ways to restart the washing machine. Both methods are successfully used, you can choose the appropriate one at will and according to the most convenient sequence of actions.

- Restart the machine so that it “forgets” the previous settings. To do this, press the Pause/Cancel button twice. This manipulation will reset the functions. With the start of the cycle after the reset, the machine will operate in the drain mode, which should not be stopped or canceled. Such actions are a normal operating condition, do not worry about it.

- Turn off the power to the machine by removing the plug from the socket or by pressing the circuit breaker of the washing machine. A half-minute pause is required before restarting.

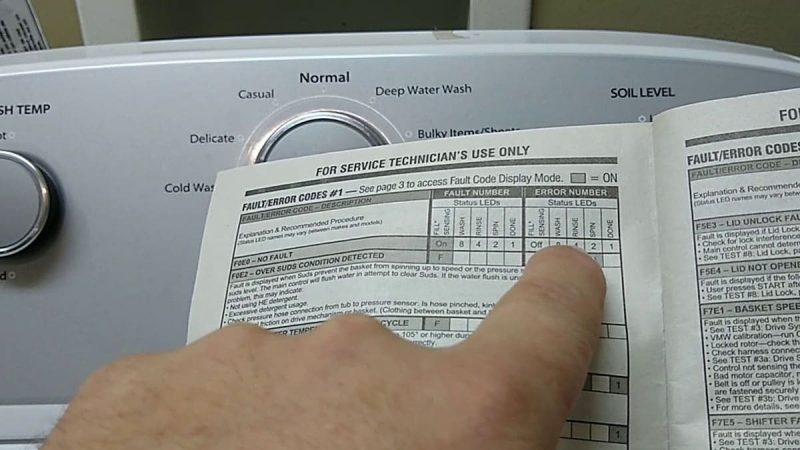

Setting to diagnostic mode

With the help of the set diagnostic mode function, the detection of problem situations is simplified, and it is possible to control the process in a test order and identify violations in the operation of individual nodes. The diagnostic mode detects the last four erroneous combinations registered by the system.

To activate the diagnostic mode on the washing machine, close the hatch correctly, then press any button on the control console, except for “Control Lock” or the “Pause / Cancel” button.

The mode starts after alternating series of button presses and pauses in the specified sequence. It is necessary to press and hold the button from 2 to 5 seconds, release it for a short second interval, the last step is to repeat the first combination of actions. These steps, repeated three times, will set the machine to the desired function, as indicated by the flashing LED light on the front. When you no longer need diagnostic mode, turn it off by double-clicking the power button.