Various breakdowns in LG washing machines occur for several reasons: improper connection and installation, non-compliance with the rules of operation and maintenance, factory defects, natural wear and tear of parts.

Some of these situations result in a repair under warranty, and in other cases, the owner has to fix the problem at his own expense. In the article we talk about the 5 most popular breakdowns in LG washing machines and how to deal with them.

Drain pump may fail after 4 to 6 years

The owner of the car notices a problem with the drainage pump when it suddenly stops draining water. A faulty node may make atypical, loud sounds during operation – this is also one of the warning signs.

The reason may be either a blockage of the pump mechanism due to the accumulation of small objects, or a breakdown of the motor or other part. In addition, if you often wash things and your area has hard water, after 4 years the pump parts wear out a lot, which also leads to breakdowns.

Before washing, make it a rule to check pockets and folds of clothes and take out coins, remove loose buttons, pins, parts from toys – all these small things get stuck in the pump mechanism and stop its operation.

In order to determine the cause of the malfunction, you need to get to the drain pump and inspect it. If small objects and debris are stuck in it, then remove them, simultaneously cleaning the pump parts from accumulated dirt. In the event of a failure of the motor or other important part, the pump will have to be replaced with a new one.

To replace the pump, use the unit device diagrams from the instructions. Before starting work, disconnect the machine from the mains and turn off the water supply. When disassembling the pump and drain hose, be aware that water may remain inside, so prepare rags and a bucket.

If you have never disassembled a washing machine before, take a photo of each assembly with an emphasis on connecting wires and screws – this will make it easier to reassemble the machine after replacing the pump. Photos will help determine the assembly sequence.

Engine harness damage

Due to damage, deformation, or a broken wire, the LG washing machine may make unusual sounds and noises during the spin cycle. For normal operation of the unit, it is necessary that all the wires in the kit are connected to the motor and power. However, due to wear and tear and misuse, one or more wires often break.

The wire may break due to too much vibration inside the machine. Or burn out due to power surges.

Broken wires lead to communication problems between the motor and the control board. The machine ends up not working properly.

To solve the problem, it is necessary to disassemble the washing unit and inspect the wiring harness. If breaks or burnt wires are found, the wires should be repaired, or the entire harness should be replaced with a new one. When completely replacing, install only certified harnesses that are suitable for your model of LG washing machine. Installing poor-quality harnesses will lead to repeated breakdown, or damage to other important machine components.

Tachometer wire break

Position sensor, or Hall sensor, aka tachometer – in the LG washing machine, this unit controls the speed of the drum and the operation of the engine. Breakage, deformation, burnout of one of the wires that are connected to the sensor leads to incorrect operation of the engine and the machine as a whole.

In order to understand the cause of a possible breakdown, you need to find a tachometer in the car and inspect the wires for damage. If they are, then it is necessary to repair or replace the entire harness.

- Unplug the washing machine and turn off the water supply.

- Turn the machine around and disconnect the water supply hoses – do this carefully, as water will pour out of them. It is better to keep a bucket and rags on hand.

- Tilt the washing machine back so that it lies horizontally with the front panel up.

- Remove the nuts and remove the rotor assembly.

- Remove the bolts that hold the motor stator.

- Carefully disconnect the wire harness connectors. Remember or capture their position in the photo.

- Connect new wires to all pins.

- Assemble the rest of the machine, connect it to the water supply and mains, check its operation.

Fill valve may stop closing

The electromagnetic inlet valve in the LG washing machine is necessary for metered water supply. Most of the time it remains in the closed position and opens only to fill with water on a signal from the control unit.

If the valve is constantly open, or does not close tightly, then it is faulty and must be replaced, since water will constantly flow into the machine, which is fraught with its failure.

Among the reasons for the failure of the intake valve may be: the car was in the cold when water froze inside the valve and its body cracked, or a problem with too hard water, which left limescale inside, which led to a breakdown.

If after washing you notice that water enters the drum even when the machine is not running, then most likely the problem is in the inlet valve.

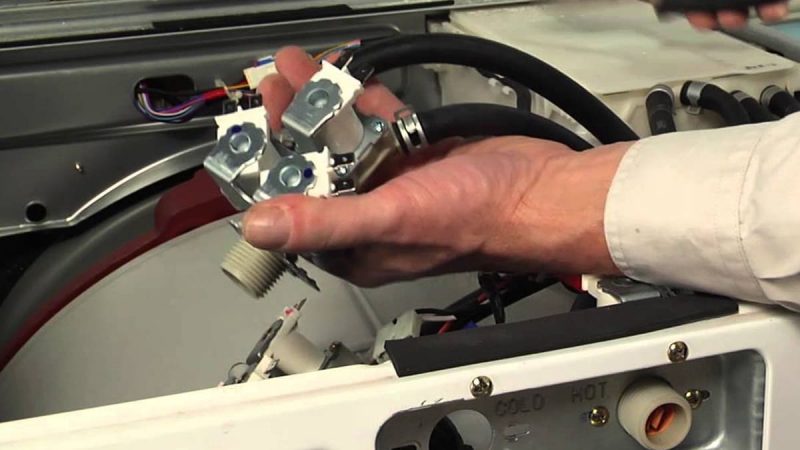

In order to make sure that the valve is broken and replace it, follow the instructions:

- Unplug the machine and turn off the water supply.

- Disconnect the inlet hoses and wait until water flows out of them.

- Remove the screws holding the top of the machine and remove it.

- Note the order in which the wires are connected to the old valve, or take a picture of them.

- Use pliers to remove wires.

- Loosen the screws holding the valve in place.

- Remove the old valve, install the new one, connect all wires and assemble the machine in reverse order.

Inlet valve leak in LG washing machine

Another common problem with the solenoid valve in an LG washing machine is water leaking onto the floor due to a broken valve. Water can be either cold or hot – depending on the type of valve.

The cause of the breakdown most often lies either in a factory defect, and then this problem is detected already in the first days and weeks of operation of the machine, or in the natural wear of parts. Water is supplied through hoses from a water supply system under constant pressure and worn valves are simply not able to withstand it, so they lose their tightness and let water through.

Before replacing valves, first check the connections to the inlet hoses and plumbing – it may be the cause of a leak in them. Then just tighten the screws. But if the problem persists, then the intake valve is faulty and will need to be replaced.