The LG brand is incredibly popular today. It produces high-quality household appliances and offers consumers several variations of clothes dryers. If you are a happy owner of such an installation, then you probably periodically have a problem with the lack of heating.

In general, there are several reasons for this phenomenon. The dryer simply does not heat up and leaves clothes damp even after a full cycle. Below we will explore a few popular reasons why this problem occurs. And also consider the guide to eliminate them.

Thermal fuse blown

Traditionally, it is included in the power supply circuit of the dryer as a protection device. The main task is to turn off the power to the heating element in case of overheating. Also, a similar element is used in a gas dryer, which is responsible for turning off the burner.

To check this part for continuity, you must use a special tool. First you will need to get access to the top of the dryer. First of all, the device is turned off, the ventilation hose is removed from the back.

The unit is moved away from the wall it is against and using a quarter inch wrench, all the screws that hold the 2 rear covers are loosened. After removing them and finding the block of the heating element, it will be necessary to remove the screw that holds the fuse and disconnect the wires connected to it. After that, you can check the system for continuity. In its absence, it is enough to simply replace the fuse.

If there is no finished product, it must be ordered. If it is, you just need to put it in place, tighten the screw and connect the wires. Next, the covers are tightened back with a wrench to 25% of an inch. Then the outlet hose is connected, the power cord is activated again, and it is tested.

Resettable High Limit Thermal Fuse Trip (Gas)

In practice, dehumidifiers are supplied with an auxiliary fuse. Its purpose is to turn off the power to the igniter when it overheats. The latter phenomenon is usually caused by the ventilation line becoming clogged, or that there has been no service cleaning for many years.

In order to reach this igniter and reset it, you must first turn off the power and then remove the exhaust by unscrewing the screw. Through the hole it will not be difficult to notice the fuse, equipped with a black button. You need to press it and reset the fuse. The user must definitely hear a click, after which it remains to put everything back and check.

Problem with igniter (gas)

If suddenly its failure is observed, the gas does not ignite, that is, there will be no heat. So, when you press the start button and start the dryer, heating will not occur. A faulty igniter is one of the most common reasons for a missing igniter.

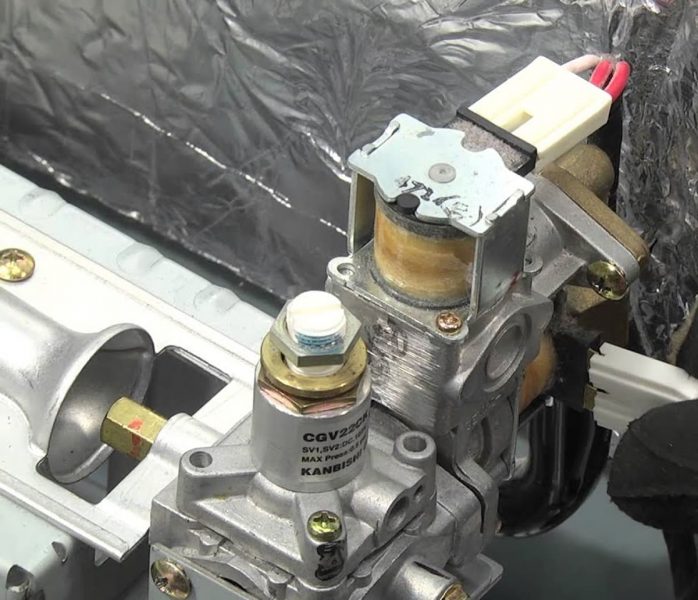

Valve assembly (gas)

It is equipped with coils for quick and easy gas passage through the burner and heat production. The total number of coils is 2 pieces. There are primary and secondary devices. Both are tested for integrity. If it fails and zero resistance is detected, the valve will not open, which means that there will be no heat.

Heating element burnout (electricity)

An electric heater is responsible for providing heat in this case. It traditionally includes one or more coils. If one coil burns out, it will cause the clothes to stop drying.

To make sure that the problem is in the heating element, you need to check it or inspect the coils. To do this, you need to gain access to the “insides” of the dryer.

For your own safety, unplug the power cord and disconnect the outlet hose. Next, the device is removed from the wall, and using a wrench, the screws that hold the covers at the back are unscrewed. They, in turn, are removed, it remains only to find the heater block.

In the next step, the wires are disconnected, the screws that hold the heating element are turned out. It is necessary to remove the heating element from the dryer and check that there are no signs of ignition of the coils on it. You can also check for continuity.

If any problems or lack of continuity are found, the heating element must be replaced. This requires maintaining contact with the manufacturer in order to order a new product. Upon receipt of the goods, you must put it in the dryer, insert the screws and tighten. And then put on the covers, return the original position of the screws. Everything, then just insert the power cord and connect the outlet hose.

Blockage in the ventilation line

The dryer of this brand has a ventilation outlet that connects to the exhaust of the house. For this, a flexible hose is used. Actually, this is another way to ensure the safety of the device.

If there is no heating, there is a high risk of destruction of the flexible hose or its clogging with fluff that has entered through the mesh in the drum. In this case, you will have to check several areas. This will help ensure that there are no obstructions.

It is logical and expedient to disconnect the system from the mains, disconnect the hose and move the unit. First, check to see if there is any accumulation of lint at the point where the hose is attached to the dryer. Next, it needs to be checked so that nothing is flattened in length. The last thing to check is the hole through which the exhaust system goes.

The hose needs to be replaced, it is important to always be able to get a new length and a replacement. When there is a new system, you need to connect it and tighten the clamp. Again, you need to activate the power cord and press it against the wall to carry out test activities.

Breakage of the control board (typical for gas and electric systems)

The main control board is the least likely cause. It should not be checked in the first place. Compared to most other components that are easy to assess, the board is much more difficult to inspect. But if other possible components have been tested or changed, then it will not be difficult to remove the control board and inspect it for burning individual elements. If a replacement is necessary, be sure to contact the manufacturer and order a part.

To remove this element, you must adhere to a certain algorithm of actions:

- unplugging the power cord;

- hose deactivation;

- moving the dryer to the wall;

- removing screws with a screwdriver;

- removal of the top cover;

- search for the main board;

- removal of all wires.

Frequently Asked Questions

Why is the dryer heating but not drying?

Most often, the fact is that the ventilation line is clogged. To check, you need to inspect the hood.

Reset Flow Cense dryer – what is it?

This technology is available in many machines. Sensors are used to determine temperatures in two areas. If there is a strong discrepancy between them, the code D80, 90, 95 will be displayed. To reset it, it is necessary to clean the dryer from the inside.

Why does the dryer trip a thermal fuse?

Such a problem is usually due to the fact that the ventilation line is clogged, or the heating element is clogged. It could also be a faulty control board.

How to fix the NP code?

It stands for “No power” and usually makes itself felt during a power failure when the dehumidifier is running on one phase. The system operates on two phases at 240 volts. As soon as one of them breaks, the heating will stop and the corresponding code will be displayed.

To correct the error, you need to make sure that the double switch does not operate. If this is indeed the case, you need to reinstall it. Then it remains to check the power at the outlet. Perhaps the point is the burnout of one of the wires and the loss of communication.